Organization & Voice

Garment workers, especially home-based workers who engage in ready-made garment production, have little if any bargaining power. They may deal only through an intermediary and have no contact with the main contractor. The intermediary may also have little power.

Most garment workers are not organized. In export processing zones, garment factories typically do not allow unionization. This is not new. In the 1990s, evidence suggests union leaders were among the first to be let go in East Asia’s garment industry when the financial crisis hit (Delahanty 1999).

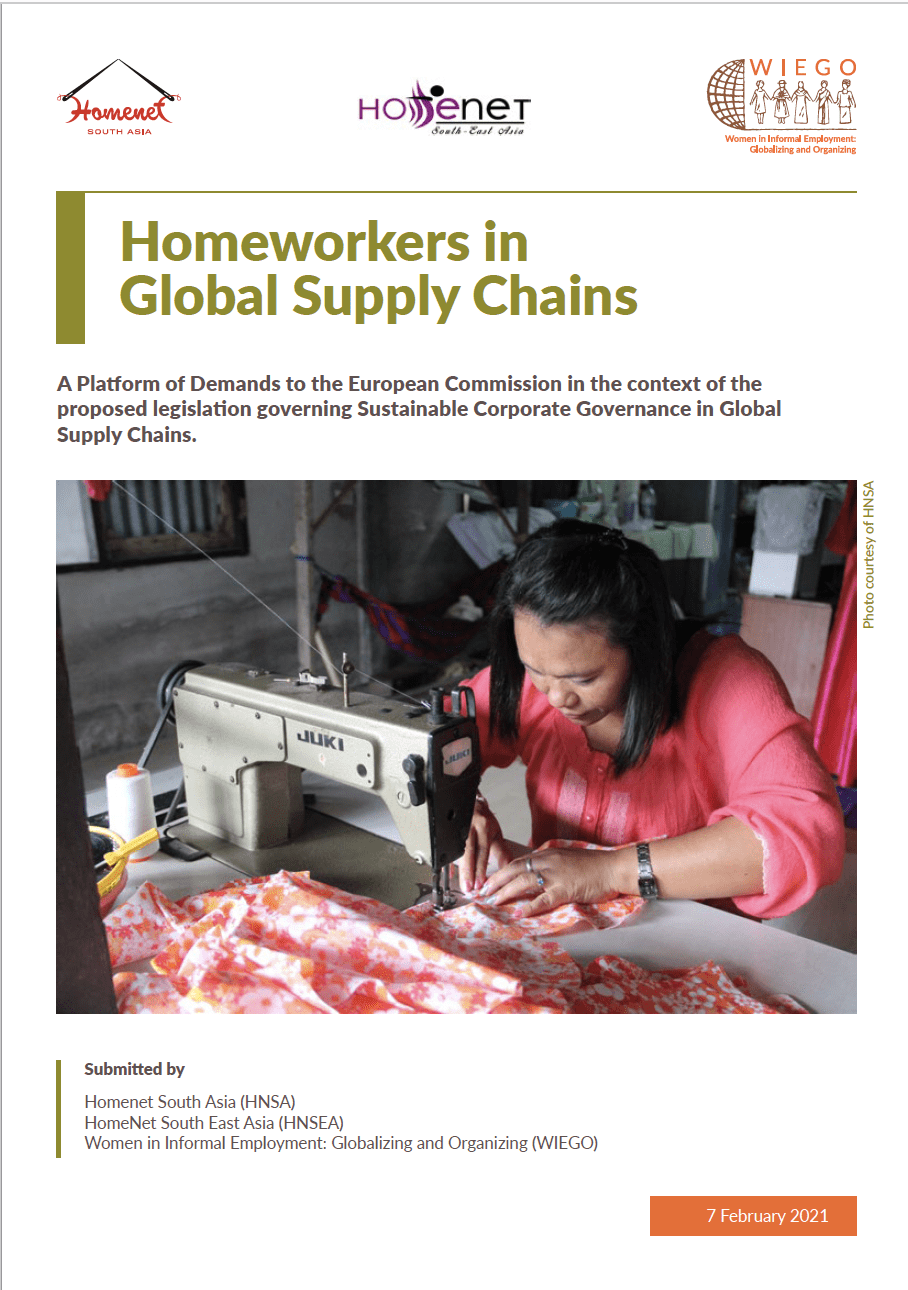

Garment makers are organizing to increase their bargaining power and, with it, their security in this globalized trade. Worldwide, there are examples of how organizing is improving the situation for these workers and the number of organizations, as well as national and regional networks of such organizations (called HomeNets), is growing.

In India, SEWA has worked to organize garment workers, concentrating on higher piece rates and fairer working conditions. In 1986, SEWA negotiated a minimum wage for garment stitching. They have helped garment workers demand better wages, working conditions, identity cards and social protection, such as child care and health benefits (Chen 2006).